crosman 2100 manual

Crosman 2100 Manual: A Comprehensive Guide

This guide details the Crosman 2100 pneumatic airgun‚ covering safety‚ operation‚ maintenance‚ and troubleshooting – referencing the official October 2023 manual.

The Crosman 2100 is a popular‚ single-pump pneumatic air rifle‚ renowned for its affordability and accuracy. This manual serves as a comprehensive resource for owners of the 2100‚ CLGY1000‚ or AM77 models‚ chambered in .177 caliber (4.5mm). Designed to function optimally with Crosman pellets‚ understanding its operation is crucial for safe and effective use.

Before operation‚ thoroughly review this manual‚ especially the safety precautions. The 2100’s design‚ dating back to 1983‚ has proven reliable‚ but proper maintenance‚ as outlined within‚ ensures longevity. This guide will help you maximize your shooting experience.

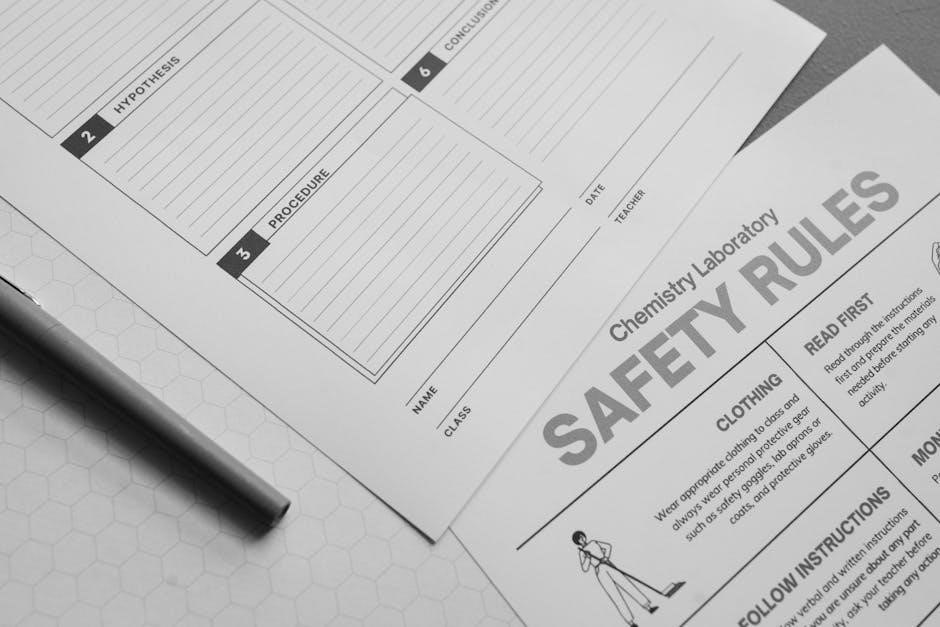

Safety Precautions

Always treat the Crosman 2100 as a real firearm. Never point it at anything you do not intend to shoot. Keep the muzzle pointed in a safe direction at all times. Before handling‚ verify the rifle is unloaded.

Adult supervision is required for users under 18. Wear appropriate eye protection during operation. Never modify the airgun‚ as this can compromise safety. Use only Crosman pellets to avoid malfunction and potential damage. Read the entire manual‚ including this safety section‚ before use. Store the rifle securely when not in use.

Understanding the Components

The Crosman 2100 is a pneumatic‚ single-shot air rifle. Key components include the barrel‚ receiver‚ stock‚ cocking mechanism‚ and trigger. An exploded view diagram (available in the manual) illustrates each part’s location and relationship. Familiarizing yourself with these components is crucial for safe operation and maintenance.

The rifle utilizes .177 caliber (4.5mm) pellets. Understanding how each part functions – from pellet loading to the firing sequence – will enhance your shooting experience and allow for effective troubleshooting when needed. Refer to the provided documentation for detailed illustrations.

Key Parts Identification

Essential components include the barrel‚ responsible for pellet accuracy; the receiver‚ housing the internal mechanisms; and the stock‚ providing a stable hold. The cocking mechanism‚ vital for preparing the rifle‚ and the trigger‚ initiating the shot‚ are also key. Identifying the breech‚ where pellets are loaded‚ is crucial.

The manual’s exploded view diagram clearly labels each part‚ numbered for easy reference. Recognizing these components – like the safety mechanism and various screws – aids in disassembly‚ maintenance‚ and understanding potential issues. Proper identification is the first step towards effective repair or modification.

Exploded View Diagram

The diagram‚ a cornerstone of the Crosman 2100 manual‚ visually breaks down the rifle into its 37 numbered components. This detailed illustration is invaluable for disassembly and reassembly‚ showcasing the precise placement of each part – from the barrel and receiver to smaller screws and springs.

It allows users to understand the internal workings and facilitates identifying replacement parts. Referencing this diagram alongside the parts list ensures accurate repairs and modifications. The exploded view clarifies complex assemblies‚ making maintenance significantly easier and reducing the risk of errors during servicing.

Loading and Pellet Types

The Crosman 2100 is designed for .177 caliber (4.5mm) pellets‚ and optimal performance is achieved using Crosman brand pellets. Utilizing alternative pellet types may lead to malfunctions or potential damage to the airgun. Loading involves carefully inserting pellets into the barrel breech‚ ensuring a secure fit for accurate shooting.

Avoid over-loading‚ as this can impede the firing mechanism. The manual emphasizes using the correct pellet size for consistent results and safe operation. Experimenting with different Crosman pellets can fine-tune accuracy based on individual preferences and shooting conditions.

Operation Instructions

Before operation‚ thoroughly read the entire manual‚ especially the safety section. The Crosman 2100 is a pneumatic airgun requiring manual cocking before each shot. Ensure the barrel is pointed in a safe direction during this process. Proper grip and stance are crucial for accuracy and control.

The firing procedure involves a smooth trigger pull after cocking. Avoid jerky movements. Familiarize yourself with the cocking mechanism’s feel to ensure consistent operation. Always double-check your target and surroundings before firing‚ adhering to all local safety regulations.

Cocking Mechanism

The Crosman 2100 utilizes a lever-action cocking mechanism. Pull the barrel rearward until it locks into place; this compresses the air for propulsion. Ensure a firm grip during cocking to avoid slippage. The cocking process requires moderate effort‚ and a distinct clicking sound confirms engagement.

Never attempt to fire the airgun without fully cocking the barrel. Repeatedly cycling the cocking lever without firing a pellet can reduce internal pressure. Always maintain a safe direction while operating the cocking mechanism‚ and avoid any distractions during this crucial step.

Firing Procedure

Before firing‚ always double-check your target and surroundings for safety. With the barrel fully cocked‚ aim carefully at your intended target. Place your finger on the trigger and gently squeeze – avoid jerking or anticipating the shot. A smooth trigger pull ensures accuracy.

After firing‚ the barrel will automatically return to its forward position‚ ready for re-cocking. Maintain a firm grip on the airgun throughout the firing process. Never dry-fire the Crosman 2100 repeatedly‚ as this can damage internal components. Always prioritize safe handling practices.

Maintenance and Cleaning

Regular maintenance is crucial for optimal Crosman 2100 performance and longevity. After each use‚ visually inspect the airgun for any signs of damage or wear. Periodically clean the barrel to remove pellet residue and maintain accuracy. Avoid using harsh solvents; a dedicated airgun cleaning solution is recommended.

Proper lubrication‚ using appropriate airgun oil‚ prevents internal friction and ensures smooth operation. Disassembly for thorough cleaning should only be performed by experienced individuals. Always refer to the official manual for detailed instructions and safety precautions during maintenance procedures.

Lubrication Guidelines

Consistent lubrication is vital for the Crosman 2100’s smooth functioning. Use only high-quality airgun oil specifically designed for pneumatic systems; avoid petroleum-based lubricants. Apply a few drops to the piston shaft during reassembly after cleaning‚ ensuring even distribution. Lightly oil the cocking mechanism’s moving parts.

Over-lubrication can attract dirt and debris‚ hindering performance. Avoid excessive oil application. Regular‚ minimal lubrication is preferable to infrequent‚ heavy applications. Refer to the official manual for specific lubrication points and recommended oil types to maintain optimal airgun operation and prevent internal damage.

Cleaning the Barrel

Regular barrel cleaning maintains accuracy and prevents lead buildup in your Crosman 2100. Use a specialized .177 caliber cleaning rod with cotton swabs or patches. Dampen the patch with airgun cleaning solvent‚ avoiding harsh chemicals. Gently push the patch through the barrel from breech to muzzle‚ repeating until clean.

Inspect the barrel for any remaining residue. A dry patch can then be used to ensure complete dryness. Avoid abrasive cleaners that could damage the rifling. Proper barrel maintenance‚ as outlined in the official manual‚ ensures consistent pellet velocity and grouping.

Troubleshooting Common Issues

Common problems with the Crosman 2100 include pellet feeding issues and reduced power. For feeding problems‚ ensure proper pellet type (Crosman recommended) and check the breech for obstructions. Low power often indicates a worn breech seal or insufficient lubrication.

Consult the owner’s manual for detailed diagnostics. Verify the cocking mechanism is fully engaging. If issues persist‚ disassembly (refer to the manual!) and inspection of internal components may be necessary. Remember safety precautions during any troubleshooting steps‚ and avoid modifications without proper knowledge.

Pellet Feeding Problems

Pellet feeding issues in the Crosman 2100 often stem from using incorrect pellet types; Crosman pellets are recommended for optimal performance. Inspect the breech area for any obstructions – debris or damaged pellets can cause jams. Ensure the pellet skirt isn’t deformed‚ hindering smooth loading.

A partially engaged cocking mechanism can also contribute. Verify full cocking action. If problems continue‚ carefully disassemble (following the manual’s instructions!) and inspect the probe and feed channel for damage or buildup. Proper cleaning and lubrication are crucial for reliable feeding.

Low Power/Velocity

Reduced power or velocity in your Crosman 2100 can indicate several issues. First‚ confirm you’re using fresh‚ high-quality pellets. Old or damaged pellets lose their effectiveness. Check the breech seal for wear or damage; a compromised seal leaks air‚ lowering pressure.

Inspect the valve assembly during disassembly (refer to the manual!). Ensure it’s clean and functioning correctly. Lubrication is vital; a dry valve reduces efficiency. Also‚ verify the cocking mechanism fully engages‚ maximizing air compression. Consistent low power suggests a deeper internal issue requiring professional attention.

Disassembly and Reassembly

Disassembling the Crosman 2100 requires caution and adherence to the official manual’s step-by-step instructions. Begin by ensuring the rifle is unloaded and safe. Carefully remove the stock‚ then proceed with the breech and valve assembly. Note the orientation of all parts for correct reassembly.

Reassembly involves reversing the process‚ paying close attention to seals and o-rings. Proper lubrication is crucial during reassembly to ensure smooth operation and prevent leaks. Refer to exploded view diagrams for accurate component placement. If unsure‚ consult online forums or seek professional assistance.

Step-by-Step Disassembly

Begin by removing the stock screws‚ carefully separating the stock from the airgun’s mechanism. Next‚ detach the breech assembly‚ noting the spring and washer placement. Unscrew the valve stem‚ being mindful of the internal o-rings. The trigger group can then be carefully removed‚ followed by the safety mechanism.

Document each step with photos for reference during reassembly. Pay attention to small parts like detents and seals. Avoid excessive force; if resistance is met‚ re-examine the procedure. Refer to the exploded view diagram (available in the manual) for visual guidance throughout the disassembly process.

Reassembly Instructions

Begin by reversing the disassembly steps‚ starting with the safety mechanism and trigger group; Carefully reinstall the valve stem‚ ensuring proper o-ring seating and lubrication. Reattach the breech assembly‚ correctly positioning the spring and washer. Secure the stock with the screws‚ avoiding over-tightening.

Utilize your disassembly photos as a guide. Test each component’s function as you reassemble. Confirm smooth operation of the trigger and safety. A properly reassembled Crosman 2100 should function flawlessly; if issues arise‚ revisit the manual and diagrams.

Crosman 2100 Modifications

Numerous modifications enhance the Crosman 2100’s performance. Common upgrades include replacing the factory valve with aftermarket options for increased power and consistency. Upgrading the breech seal and o-rings improves air retention. Many enthusiasts explore custom stocks and grips for improved ergonomics.

Aftermarket parts‚ readily available online‚ allow for significant customization. Be aware that modifications may void warranties and require advanced mechanical skills. Research thoroughly before attempting any alterations‚ prioritizing safety and proper function. Comparisons with the Crosman 397 often drive modification choices.

Common Upgrade Paths

Popular upgrade paths for the Crosman 2100 focus on power and accuracy. A frequently chosen modification is installing a higher-flow valve‚ boosting velocity and shot count. Polishing internal components‚ like the compression chamber‚ reduces friction for smoother operation. Many users replace the stock barrel with a rifled aftermarket barrel for improved pellet grouping.

Another common path involves upgrading the pump linkage for easier cocking. Exploring different spring combinations can fine-tune the power level. Remember to research compatibility and potential impacts on the airgun’s lifespan before implementing any upgrades.

Aftermarket Parts

A robust aftermarket supports the Crosman 2100‚ offering numerous customization options. High-flow valves from companies like TJ’s Airgun Parts significantly increase power. Rifled barrels‚ available in various lengths and materials‚ enhance accuracy. Upgraded breech seals improve air retention and consistency.

You can find replacement springs‚ pump linkages‚ and even complete bolt assemblies. Custom grips and stocks provide a more comfortable shooting experience. Ensure parts are specifically designed for the 2100 to guarantee proper fit and function. Online forums are excellent resources for identifying reputable suppliers and compatible components.

Comparison with Crosman 397

Both the Crosman 2100 and 397 are single-pump pneumatic air rifles‚ popular for their affordability and simplicity. The 397 generally offers slightly higher velocity due to its design‚ but the 2100 is often favored for its ease of modification. Disassembly and reassembly are considered simpler on the 2100.

Parts availability is good for both models‚ though the 2100 boasts a larger aftermarket. Some users find the 397’s shoulder stock more comfortable. Comparisons reveal that the 2100’s performance can be significantly enhanced with aftermarket upgrades‚ potentially surpassing the 397’s stock capabilities.

Manual Download and Resources

The official Crosman 2100/CLGY1000/AM77 manual‚ a 939KB PDF published October 17‚ 2023 (MD5: 338DD86A61BC702FC47B6FD9F62235A7)‚ is directly available from Crosman’s website. This comprehensive document covers safety‚ operation‚ and maintenance.

Beyond the official manual‚ numerous online forums and communities dedicated to airguns provide valuable resources‚ troubleshooting tips‚ and modification guides. Websites often host exploded view diagrams and parts lists. Crosman’s own site (crosman.com/cs/manuals/crosman-rifles) is a central hub for support.

Official Crosman Manual Link

Access the official Crosman 2100/CLGY1000/AM77 .177 Caliber (4.5 mm) Pneumatic Airgun owner’s manual directly through Crosman’s website. This crucial 939 KB PDF document‚ last updated October 17‚ 2023‚ provides detailed instructions on safe operation‚ maintenance‚ and troubleshooting.

The manual’s MD5 checksum is 338DD86A61BC702FC47B6FD9F62235A7‚ ensuring file integrity. You can find the direct link within the Crosman rifles manuals section at crosman.com/cs/manuals/crosman-rifles. Downloading and reviewing this manual before use is strongly recommended.

Online Forums and Communities

Enhance your Crosman 2100 experience by connecting with fellow enthusiasts online! Numerous forums and communities offer valuable insights‚ modification ideas‚ and troubleshooting assistance. These platforms are excellent resources for learning from experienced users and sharing your own knowledge.

Discussions often cover topics like upgrade paths‚ aftermarket parts‚ and comparisons with models like the Crosman 397. While specific forum links aren’t provided‚ a general web search for “Crosman 2100 forum” will reveal active communities dedicated to this popular airgun. Engage‚ learn‚ and contribute!

Specifications of Crosman 2100

The Crosman 2100 is a .177 caliber (4.5 mm) pneumatic airgun‚ designed for optimal performance with Crosman pellets. While detailed specifications aren’t explicitly listed in the provided information‚ it’s understood to be a single-pump pneumatic rifle. The owner’s manual‚ available as a 939 KB PDF (MD5 Checksum: 338DD86A61BC702FC47B6FD9F62235A7‚ published October 17‚ 2023)‚ likely contains precise details.

Users frequently compare it to the Crosman 397‚ suggesting similar operational principles. Further research and the official manual will reveal specifics regarding velocity‚ weight‚ and overall dimensions.